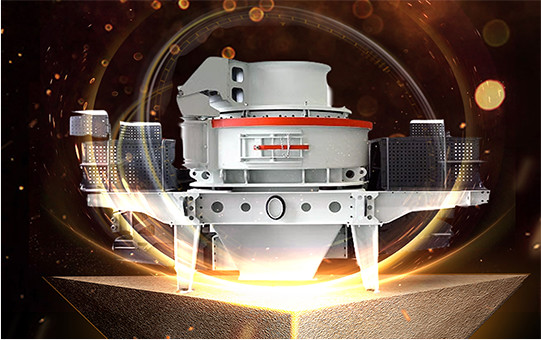

In the 1980s, foreign countries successfully launched the first self-impact vertical shaft crusher, which brought about a revolution in the crushing industry. This machine is suitable for the crushing and shaping of soft or medium hard and extremely hard materials. It is widely used in various ores, emery, machine-building sand, stone materials and various metallurgical slags, especially for high-hard, extra-hard and wear-resistant materials More efficient than other types of crushers. It is reported that in the early 1990s, foreign vertical shaft impact crushers were used for production in the super-large sand and gravel systems of the Xiaolangdi Project and the Three Gorges Project in China.

For this reason, since 1992, domestic companies have started to develop vertical shaft impact crushers. At present, Sanming Heavy Industry, a subsidiary of Chongqing Longjian Industrial Group, has successfully launched PL vertical shaft impact crusher series products, which are suitable for various crushed materials with compressive strength not greater than 320MPa, such as iron ore, copper ore, gold and silver ore, Hundreds of types of aluminum ore, lead-zinc ore, tungsten ore, manganese ore, glass raw materials, refractory materials, ceramic cement, corundum for construction, olivine, rock salt, fluorite, limestone, cobblestone, carbonized silicon steel slag, etc. The fine crushing of hard and corrosive materials has the advantages of simple structure, smooth operation, high efficiency and energy saving, small wear and tear, and convenient maintenance.

Generally, the vertical shaft impact crusher uses the diameter of the impeller as the standard for dividing the specifications. According to the form of the impeller, it is divided into open type and closed type; according to whether the outer shell is equipped with a counter plate, it can be divided into two types of crushing methods, stone and stone, and the combination is 4 A basic form. The rotor is the key component of the vertical shaft impact crushing mechanism. Whether the rotor is designed properly or not directly determines its crushing performance.

1. Working Principle of Vertical Shaft Impact Crusher

Vertical shaft impact crusher is mainly composed of feed hopper, rotor, main shaft, vortex crushing cavity, transmission mechanism, frame, lubrication device and other parts. Its working principle is as follows:

1. The material passes through the hopper to form a vertically downward material flow under the action of gravity, enters the top of the rotor cone cone through the falling ring and is evenly distributed into multiple horizontal material flows. In the rotor acceleration channel, the rotor rotates The strong impact of the wave first produces strong squeezing and grinding and crushing, and is subjected to the rotation and impact of the throwing head at the end of the acceleration channel.

2. Under the action of centrifugal force exerted by the high-speed rotating rotor, the horizontal stream is rapidly accelerated from the acceleration channel to a linear velocity of 65 m / s to 75 m / s and at the same time obtains huge kinetic energy. When the cavity collides with the material cushion (stone-to-stone model) or anvil (stone-to-iron model), the energy between the intense kinetic energy and the crushing energy is fully converted to produce collision and crushing. The material whose kinetic energy is completely converted into crushing energy will be chased by the continuous flow of horizontal material provided by the high-speed rotor to produce continuous crushing, and tangential ejection will also produce high-speed extrusion, grinding and crushing.

3. The material after the horizontal impact cannot be completely released due to the huge material flow energy, and it will reverse sputtering. If the sputtering enters the rotor movement area, it will encounter the exquisitely structured rotor counterattack and form counterattack crushing.

4. A dense high-speed vortex particle cloud is formed between the high-speed rotating rotor and the barrel wall of the vortex crushing chamber. The materials chase each other to establish a continuous high-energy collision, extrusion, grinding, and a continuous high-energy collision chain composite reaction process. .

Second, the main problems of the rotor of the vertical shaft impact crusher

The rotor is the key component of the vertical shaft impact crusher. Whether the rotor is designed properly or not directly determines its crushing effect. The rotor is mainly composed of rotor body, throwing head, deflector, inner and outer protection ring, counterattack plate, material distribution plate, etc. It only accelerates the material and does not crush the material, but the material needs to obtain kinetic energy from the rotor to collide with the crushing chamber wall and the material lining to achieve crushing. The crushed material enters from the center of the rotor by its own weight, and is accelerated by the high-speed rotating rotor. Due to the centrifugal force, the material is projected into the crushing chamber from the blasting port around the rotor at high speed. The inside collides with the material lining repeatedly and impacts, and the grinding breaks.

At present, at home and abroad, the vertical shaft impact crusher is basically designed with a bolt connection for the rotor, and the outer protective ring is welded. The rotor of this structure has the following main problems in use:

1. Because the throwing head will be subjected to centrifugal force of several tons to tens of tons in rotors of different sizes, its bolt will be greatly pulled; at the same time, due to the impact of the high-speed movement of the material, the bolt will easily break and fail. Instantly lose the dynamic balance, causing huge damage to the equipment.

2. Since the outer protective ring adopts surfacing welding, the surfacing part of the rotor is worn when it is working, so it must be re-surfacing before it can be used. This will damage the original dynamic balance of the rotor, and losing the balance of the rotor is easy to cause equipment damage.

3. The improved design of the rotor of vertical shaft impact crusher

According to the existing problems of the rotor structure of the vertical shaft impact crusher, the following improvements have been made: 1) The throwing head is directly inserted into the circular hole of the upper and lower discs. The rotor will produce several tons to tens of tons during high-speed movement. Centrifugal force acts on the bolt. During the movement of the rotor, the acceleration of the material is l 000-1500 times of the acceleration of gravity. Using the traditional bolt connection method, the strong impact force will break the bolt, causing an imbalance in an instant, which will cause the host to appear. Major failure.

To this end, Chongqing Longjian Industrial Group Co., Ltd. continuously improves and innovates and improves the design from the following aspects:

1. Abandon the traditional connection method of the bolt connection between the throwing head and the rotor, and insert the throwing head directly into the circular holes of the upper and lower discs. The strong centrifugal force and material impact force generated by the throwing head during high-speed movement will be made of high strength The transfer body and the throwing head are used for sharing. The throwing head adopts high wear-resistant buffer plug-in type throwing head, which is composed of the throwing head, cemented carbide and elastic buffer sleeve. The throwing head is directly inserted into the circular holes of the upper and lower discs while adopting elasticity in the insertion hole Filling the filler, so that the alloy on the throwing head can avoid the impact peak of the material, improve the impact resistance and anti-iron resistance, due to the use of buffer connection, it can use hard alloy with high micro hardness to improve its wear resistance , Greatly improve its stress situation, improve the service life of the rotor and the reliability of the equipment.

2. The outer protective ring of the rotor adopts surfacing welding. Because the surfacing part of the rotor is worn out, it must be resurfacing to be used. This causes the original dynamic balance of the rotor to be damaged, and the rotor that is out of balance is easy to cause equipment damage. In the improved design, the upper and lower outer protection rings are bolted to the outer circle of the rotor body, the upper inner protection ring is bolted to the inner circle of the rotor body, and the upper inner protection ring and the upper outer protection ring simultaneously fix the upper disc at On the rotor body. After the improvement, the wear-resistant electrode is not welded on the rotor base body, but only the protection ring needs to be replaced to ensure the service life of the rotor. At the same time, the problem of dynamic imbalance caused by the welded wear-resistant parts after the rotor wear is eliminated. The substrate is made of highly wear-resistant material, and the latest scientific and technological achievements are used on the surface for w-c (tungsten alloy) co-infiltration, which greatly improves the service life of the protective ring, and the rotor body protection is more perfect. It has been used in limestone areas for at least 3 years life.

3. The rotor matrix is ??made of high-strength, high-wear-resistant structural steel plate, which has high strength and high wear resistance.

4. Aiming at highly abrasive materials, the distribution plate adds cushioned alloy or ceramic wear-resistant blocks, which greatly enhances the rotor's anti-wear performance.

5. A counterattack plate is designed on the rotor to further strike the rebound material, and the probability of crushing further increases. Before assembly, the rotor assembly undergoes strict static balance and dynamic balance tests to ensure the smooth running of the main engine.

In order to achieve the goals of high efficiency and energy saving of equipment, good shape of crushed materials, high reliability, long service life and low operating cost, Sanming Heavy Industry of Chongqing Longjian Industrial Group constantly innovates and improves. At present, the PL vertical shaft impact crusher we have developed has been exported to all parts of the country, as well as South America, South Asia, Southeast Asia, West Asia, Africa, Australia and other parts of the world, and has won unanimous praise from many customers.

Keywords: Impact Crusher Longjian Group

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association